Coupling is a transmitter of rotating energy from oneend shaft to another. This device is in most electric motors for the distribution of mechanical energy. A universal coupling does not exist by design. It can have various forms and design features.

Electromagnetic clutch, like any other, is a combination of the following parts:

If these parts are connected, not displacing, then we get a permanently connecting part.

In the automotive industry, couplings are widely used, the two main parts of which are connected by an electric field and a magnetic field.

Couplings are divided as follows:

To mechanical carry:

Induction refers to:

Any of their above-mentioned principles of operation does not change the main purpose of the coupling: the conversion of the input of mechanical energy into it at the output.

For control and automatic systems, all types of couplings can be used.

The work of induction elements corresponds to the work of an electric motor. Therefore, the most widespread are the following devices:

With such a part, it is possible to connect the parts both rigidly and with the slip of the driven from the drive.

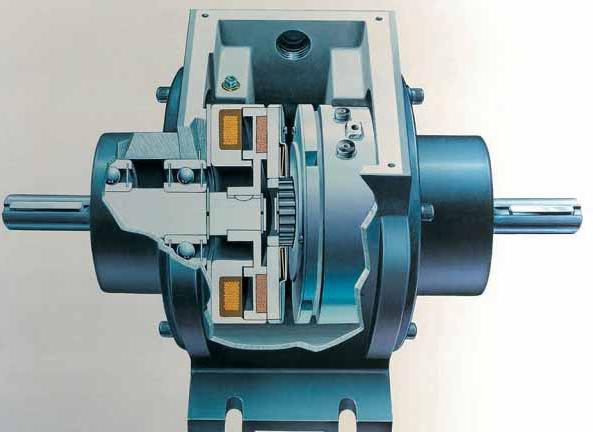

The construction of the element is as follows. Both parts of the coupling are steel cylinders, which are magnetic cores. In the driven part there is a groove to which the excitation winding is fed. It, in turn, is connected to a power source by means of contact rings together with a brush. The space between the parts is filled with a ferromagnetic mixture. It can be powdery or liquid.

When a DC voltage is applied to the winding,there is a current that forms an exciting current. It passes through a ferromagnet and magnetizes the latter, its particles are created by magnetized chains.

When the force closes in the mechanicalthen the part can be called a friction clutch or a friction clutch. To connect such a part is possible with the engines, which are activated under heavy load. Structurally, these elements can be made from one or more disks with a different friction surface design: in the form of a cylinder or a cone.

Surfaces susceptible to friction are joined togetherelectromagnetic field. Adjust the torque of such a friction clutch is not, it's permanent. Change under the influence of a change in the magnitude of the current, it is not subject. To increase the power this clutch can with a factor of more than 30.

Electromagnetic elements have a subdivision depending on the field of their application.

Protect devices and various mechanisms from the overload of impulse only this part is capable.

In the front of the compressor is installed it. It consists of the basic elements: a plate, a pulley, an electromagnetic coil.

The plate is attached directly to the shaft, andthe coil and the pulley have an arrangement on the front cover. When the power supply that creates the magnetic field begins, the plate is attracted to the pulley and the compressor shaft starts to move. The pulley rotates together with the plate.

If the electromagnetic clutch is broken, it can be repaired by yourself.

If the question arose of replacing such a detail aselectromagnetic coupling ("GAZelle" is no exception), then problems with finding the necessary equipment should not arise. It's good if the breakdown was discovered on time. This will avoid additional costs in the event of failure of other, connected parts of the engine.

Couplings for different equipment are also different, and in order not to be mistaken for self-purchase, you can contact the service center.

If the electromagnetic clutches of the compressor fail, the reasons for this may be the following:

The electromagnetic fan clutch is used to cool the car compressors or to maintain a certain engine temperature.